Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2023-10-20 13:58:22

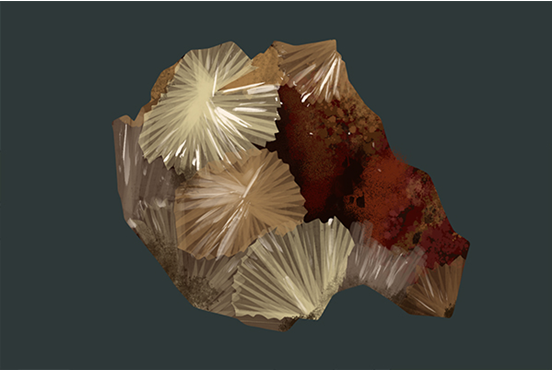

Pyrophyllite is an important non-metallic mineral resource. There are many pyrophyllite production enterprises in my country, but the intensification of the pyrophyllite industry is not obvious enough. In recent years, with the continuous development of economy, pyrophyllite has been "revitalized" in the applications of glass fiber, refractory materials, new materials and other fields.

In order to expand the scale of the fiberglass industry, Chinese giants in the fiberglass industry are investing in projects in Jiangxi and need to build a pyrophyllite powder production line. The company inspected many powder processing equipment manufacturing companies, and after layers of screening, it finally chose HCM Hongcheng Machinery to help it build a pyrophyllite powder production line.

In order to expand the scale of the fiberglass industry, Chinese giants in the fiberglass industry are investing in projects in Jiangxi and need to build a pyrophyllite powder production line. The company inspected many powder processing equipment manufacturing companies, and after layers of screening, it finally chose HCM Hongcheng Machinery to help it build a pyrophyllite powder production line.

Pyrophyllite is a clay mineral with low hardness. It has the characteristics of high temperature resistance, chemical corrosion resistance, poor electrical conductivity and plasticity. It is widely used in ceramics, refractory materials, glass fiber and other industries. Pyrophyllite powder is hydrated aluminum silicate fine powder, which is also widely used in emerging industries such as high-end equipment manufacturing, new energy, and biotechnology.

When pyrophyllite is used in fields such as fiberglass and refractory materials, it needs to be ground to a certain fineness before it can be used. At present, the vertical mill has become the mainstream equipment to promote the large-scale production of pyrophyllite. As an expert in powder equipment manufacturing, HCM Hongcheng Machinery’s HLM series of vertical mills have strong adaptability to pyrophyllite. The equipment is efficient and energy-saving, and the finished products are of high quality. Enterprises have reported very good results from the use of the equipment.

HCM vertical mill pyrophyllite project case

Equipment model: HLM22/3K vertical mill

Processing materials: pyrophyllite, kaolin

Finished product fineness: 325 mesh D99

Production capacity:14-17t/h

Technical advantages and features: integrated design, one machine for multiple purposes

It integrates crushing, drying, grinding, grading and conveying, with a compact layout; it can be used for grinding a variety of materials, reducing investment costs.

It has high grinding efficiency, good discharge quality, high classification accuracy and high grinding efficiency; the finished product has uniform particle size distribution, good quality, good fluidity and high activity.

It is easy to maintain and has a high degree of automation. It adopts PLC fully automatic control system, which can realize remote control, reduce labor, improve work efficiency and reduce maintenance costs.

It is high-yield and wear-resistant, energy-saving and environmentally friendly. It adopts wear-resistant surfacing roller sleeves, which has low wear and large single-machine production capacity. The whole machine system has small vibration and low equipment failure rate. The entire system is sealed and operates under full negative pressure, with no dust spillage.

With more than 30 years of production experience, HCM Hongcheng Machinery continues to provide customers with a variety of series of grinding machines, builds professional and high-quality grinding production lines for customers with high-quality products and high-quality services, helps customers create huge value, and wins Favored by our customers.

With more than 30 years of production experience, HCM Hongcheng Machinery continues to provide customers with a variety of series of grinding machines, builds professional and high-quality grinding production lines for customers with high-quality products and high-quality services, helps customers create huge value, and wins Favored by our customers.

In the next step, HCM will continue to improve its grinding equipment technology, provide higher-quality grinding equipment for pyrophyllite grinding enterprises, help the development of the pyrophyllite grinding industry, meet the industrial scale, refinement, and intensive grinding needs, and provide pyrophyllite Provide guarantee for industrial green transformation and development! Welcome to learn more, email address:mkt@hcmilling.com